Air Flow Control Valve for Upper Blackstone Wastewater Treatment Plant in Millbury, MA

IRIS Control Valve In the FieldScope:

(4) DN250 – 10” valves, actuators, piping and flow meters, 820-4160 scfm.

(8) DN125 – 5” valves, actuators, piping and flow meters, 280-690 scfm.

(16) DN100 – 4” valves, actuators, piping and flow meters, 210-1390 scfm.

Engineer:

CDM Smith

Contractor:

MWH Constructors

Date:

2018

Wastewater Treatment Plant

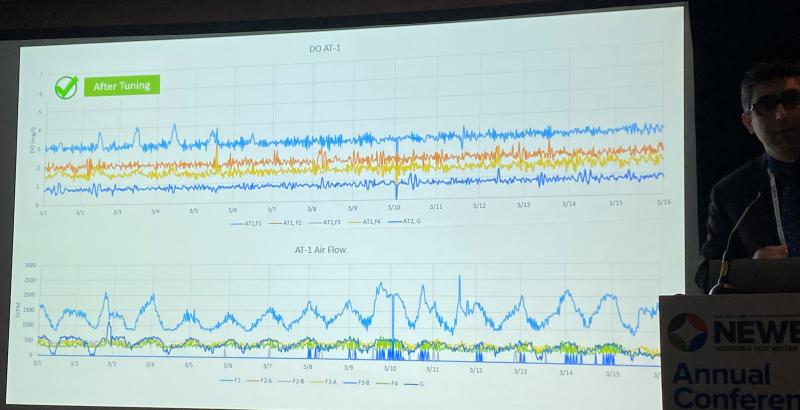

Together with CDM Smith & MWH Contractors, Egger’s IRIS Process Control Valves helped Upper Blackstone Clean Water to achieve their DO control goals while reducing power consumption 10%, significantly reducing labor hours via valve automation with MOV strategy, while reducing the need for supplemental carbon feed by 50%.

Precise airflow control with Iris Valves – Upper Blackstone

Economical and precise regulation of aeration air at Upper Blackstone Waste Water Treatment Plant

Iris® diaphragm control valves enable the stable and repeatable regulation of media over the entire valve stroke. For gases and aeration air, the Iris® valves are designed so that the quantity to be regulated can be operated within a high control-accuracy range without hysteresis. Its unique design with six centrally opening segments which can be retracted completely into the casing results in an equal-percentage valve characteristic for the Iris® valve. This leads to a virtually linear operating characteristic curve with a large control range, enabling the operation of economical control loops. The differences in the operation of control valves and Iris® diaphragm control valves can be briefly explained using the example of the Upper Blackstone wastewater treatment plant in the Federal State of Massachusetts (USA).