Brightwater Treatment Plant – Woodinville, WA (Aeration Basin Upgrade)

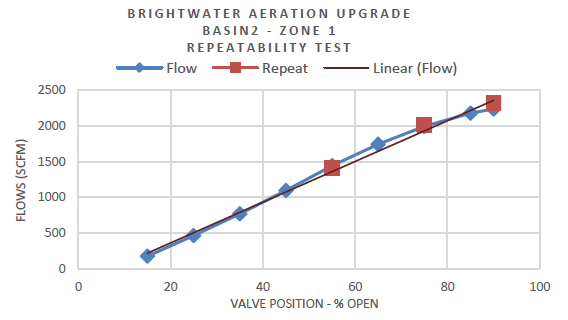

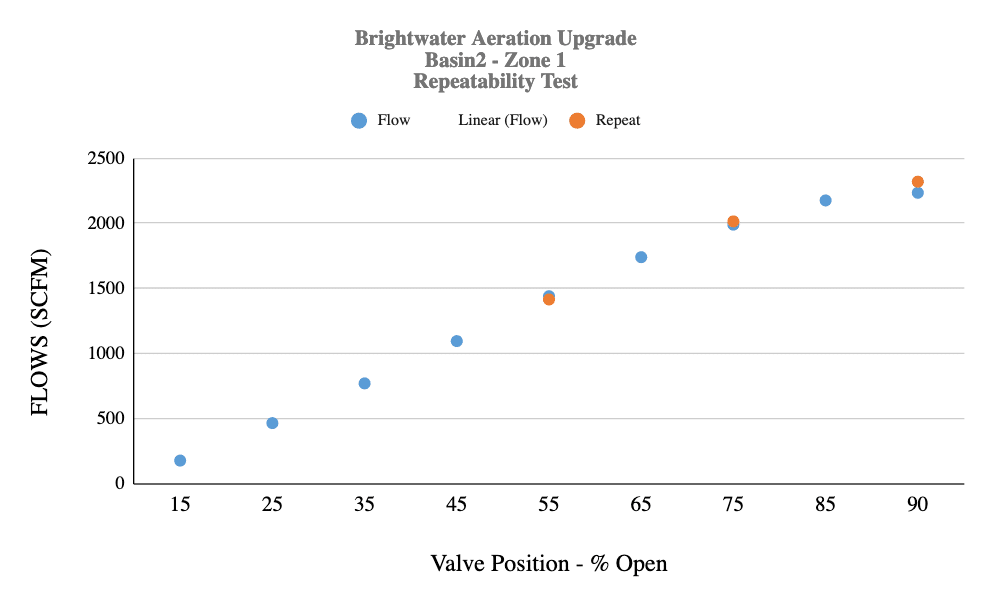

Success Story About IRIS Control ValveWe conducted an Iris Valve “Repeatability” test at King County’s – Brightwater Treatment Plant in Seattle, WA and recorded a > 99% Repeatability! This is real-world data, recorded in the field, and witnessed by Brown and Caldwell Engineers!

Three (3) tests were run on Basin 2 – Zone 2 (8” Iris valve):

- Repeatability test at 90% Open

- 1st – Measured 1,800 SCFM at 90% Open

- 2nd – Closed valve to 30% for 1-minute

- 3rd – Opened valve back to 90%

– observed 1,791 SCFM (1,800 – 1,791 = 8 SCFM)

- Repeatability test at 75% Open

- 1st – Measured 1,588 SCFM at 75% Open

- 2nd – Closed valve to 30% for 1-minute

- 3rd – Opened valve back to 75%

– observed 1,575 SCFM (1,588 – 1,575 = 13 SCFM)

- Repeatability test at 55% Open

- 1st – Measured 1,190 SCFM at 55% Open

- 2nd – Closed valve to 30% for 1-minute

- 3rd – Opened valve back to 55%

– observed 1,173 SCFM (1,190 – 1,173 = 17 SCFM)

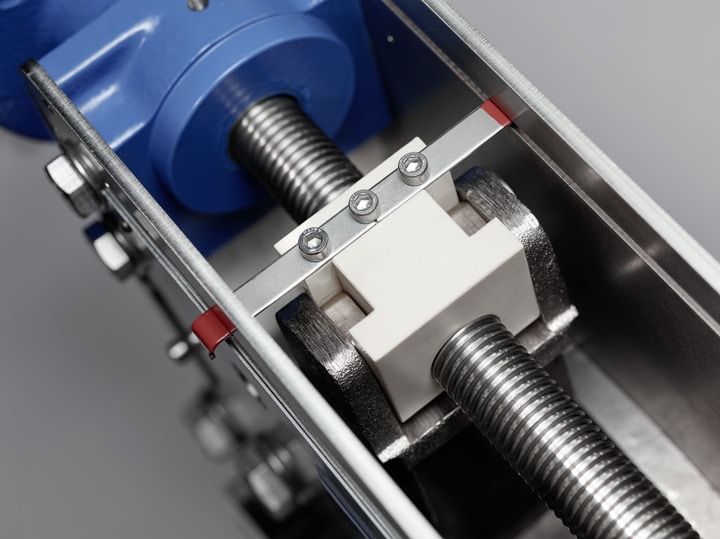

Egger’s patented Iris valve uses a robust “Spindle” control assembly:

- Spindle assembly rotates an external drive nut to precisely open and close the valve.

- Spindle actuation is mounted externally for easy maintenance.

- Spindle uses a rigid bearing support (other valves, this work is done by the actuator).

- Spindle mounted pointer provides exact valve position.

- Quality multi-turn actuator is hard-mounted to our flange.

- The Spindle on an 8” Iris valves travels 62 turns to Full Open & 62 turns back to Full Close or a length of 7.3 inches.